Our Products

With over 100 years of collective technical experience, the team at Boss are perfectly positioned to offer our expertise in assisting you with your projects. We work in conjunction with your team to turn ideas into reality. Together, (or we are happy to take full responsibility) we will develop the best and most cost efficient design for your project. Our Chemist will take into account all elements of the application and design to select the most appropriate raw material. We offer rubber, rigid and soft plastics, engineering plastics and much more. Certificates of conformance and material data sheets are available upon request.

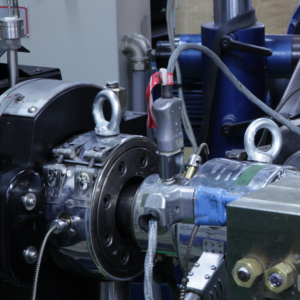

Design, development and testing of high quality, fine tolerance tools are Boss specialty skills, gained through a long tradition of manufacturing. At Boss, tool design expertise is a vital element in delivering quality polymer products to customers in a range of industries that demand high tolerances and product performance, such as automotive and weather sealing products.

Computer aided design (CADCAM) is used and methodical testing in real world situations is carried out. Off Tool Samples may be supplied to enable you to prove the product prior to production.

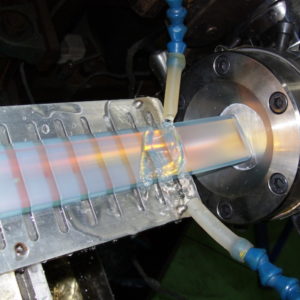

Creative tooling design is the major contributor to successfully delivering the Boss ExWeld self-adhesive tape technology to the world, which was recognised by the Society of Automotive Engineers Australasia Bronze Award for Automotive Engineering Excellence, and is now being adopted in a range of industries.

Explore our extensive range of extrusions & profiles: rubber extrusions & profiles, plastic extrusions & profiles