Our Products

Home » Mining, Screening & Refining

Over the decades, Boss has worked alongside many leading Australian and international mining companies to develop innovative solutions to some of the most complex mining requirements. Working with these clients as partners, Boss has developed heavy-duty products that are designed to increase efficiency, safety, support contamination prevention, improve up-time, reduce costs and optimise and extend the service life of their mining equipment. Ongoing contracts include railway shims, specialty gaskets, explosive tubing, capping rubbers and general purpose industrial rubber. Our engineering expertise and skill in polymer chemistry allows us to advise you on the most appropriate polymer selection and design to suit your particular application.

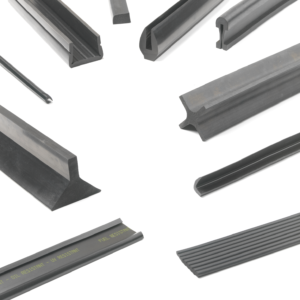

Explore our extensive range of extrusions & profiles:

–rubber extrusions & profiles

–plastic extrusions & profiles

–custom bespoke rubber solutions

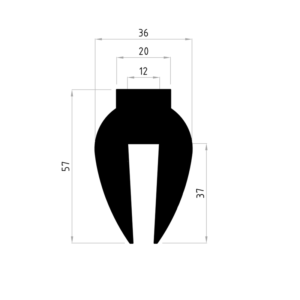

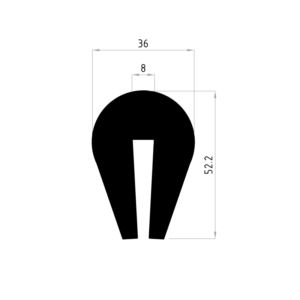

Rubber Industrial Structural Seals

View more

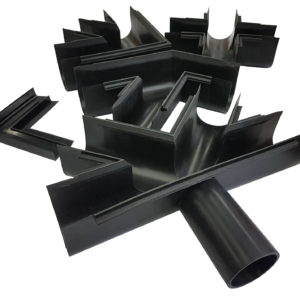

Mouldings

View more

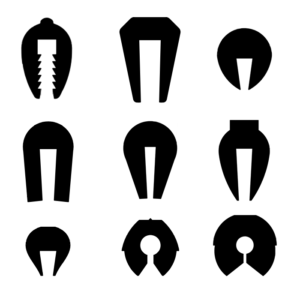

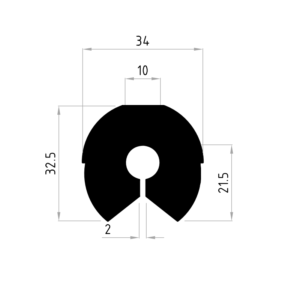

Capping Rubbers

View more

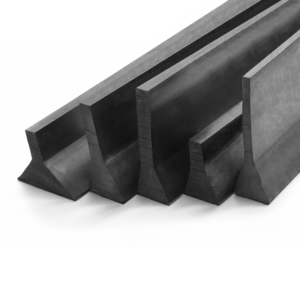

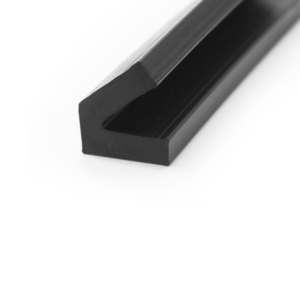

Rubber Conveyor Profiles

View more

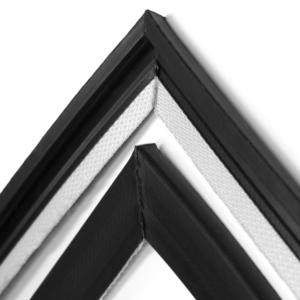

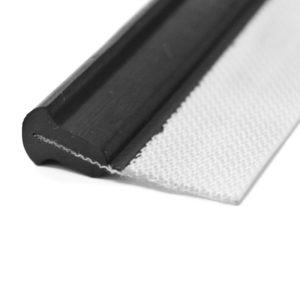

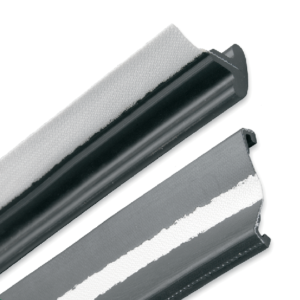

Filtration Extrusions

View more

Miscellaneous Profiles

View more