Home » Rubber Extrusions & Profiles » Industrial Structural Seals

For decades, Boss Polymer’s rubber specialists have partnered with architects, engineers, and construction firms to deliver high‑performance rubber structural seals. These products protect buildings and infrastructure from water, air, vibration, and structural movement, providing long‑lasting durability in even the harshest conditions.

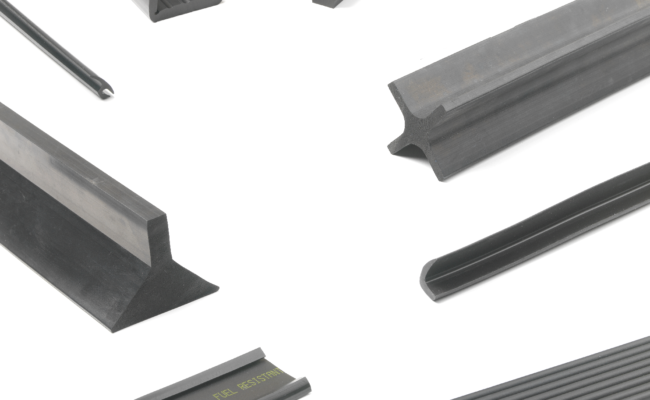

Rubber remains one of the most versatile and reliable materials for structural sealing applications. Our extrusion expertise allows us to manufacture sealing systems that perform consistently across commercial buildings, infrastructure, and heavy industry.

Key Benefits of Rubber Structural Seals

Rubber structural seals are valued for their flexibility and resilience. They conform easily to irregular surfaces and maintain effective sealing force even after years of compression. Their ability to withstand environmental stresses—such as water, UV, ozone, and temperature extremes—makes them suitable for indoor and outdoor applications alike.

Another important advantage is their natural vibration and impact absorption, which allows rubber seals to protect joints and structures in environments subject to movement or heavy machinery. With a wide range of compounds available, including EPDM, neoprene, nitrile, viton, sponge rubber, and thermoplastic elastomers such as Santoprene, each project can be matched with a material suited to its performance and environmental demands.

Applications

Boss Polymer designs and manufactures rubber structural sealing systems for a variety of industries. These seals are commonly found in expansion and movement joints within industrial and commercial construction, where they accommodate building dynamics while keeping joints secure. They also form part of façade, window, and door assemblies, providing airtight and watertight protection.

Our rubber seals are relied upon in heavy industries such as mining and rail, where exposure to constant vibration, dust, and weathering demands materials that maintain long‑term integrity. They are equally effective in machinery housings, industrial enclosures, and equipment operating under demanding environmental or chemical conditions.

Rubber Extrusion Capabilities

Boss Polymer offers a complete range of extrusion solutions for structural sealing. This includes cross‑head and co‑extruded profiles, as well as self‑adhesive rubber products for faster and easier installation. Profiles can be supplied as solid or sponge sections, flexible or rigid, and even in multi‑compound constructions combining up to three rubber materials for enhanced performance.

Through our ongoing investment in advanced extrusion technologies, we are able to provide sealing systems that balance durability, precision, and cost‑effectiveness.

A Trusted Partner in Rubber Sealing

Our long history in rubber development, combined with ongoing technical innovation, allows us to deliver tailored sealing systems for projects of every size and complexity. From standard profiles to proprietary lines and fully customised designs, Boss Polymer manufactures rubber structural seals that deliver reliable protection and lasting performance.

Contact Boss Polymer

Reach out to the Boss team to discuss your specific rubber requirements. View our extensive range of rubber extrusions and profiles.