Home » Silicone Extrusions & Profiles » Facade Gasket & Seals

Located south-east of Melbourne, Australia, the Boss Polymer plant in Mulgrave manufactures a complete range of silicone façade gaskets and seals in a vast range of silicone compounds. Silicone façade gaskets and seals are utilised for various purposes across numerous industries, particularly in the construction of high-rise buildings.

Durable Silicone for Challenging Climates

Our silicone façade gaskets and seals are engineered to withstand a variety of challenging elements and climates. This includes performance in extremely hot conditions, high ozone and UV levels, extreme rain, and strong winds.

Custom Silicone Designs for Façades

Boss Polymer specialises in collaborating with clients or their architects to create speciality and custom-designed silicone solutions for façades. The design of these silicone products is crucial for several aspects of construction. Whilst aesthetics are a key element for many projects, silicone designs must also take structural movement into consideration due to their function as dampeners, preventing draughts and protecting against moisture absorption.

Precision Silicone Manufacturing Capabilities

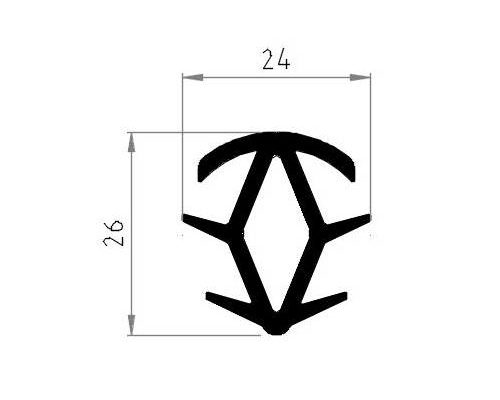

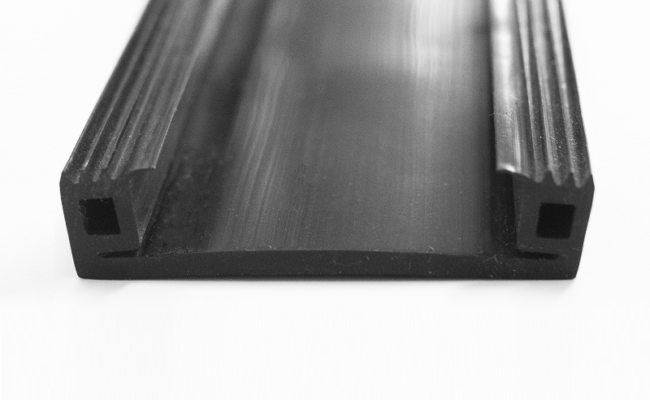

Boss Polymer possesses the technical capability and high-end on-site equipment to design and produce the best quality, high-precision silicone products, including a range of intricate and unique silicone shapes. Silicone façade gaskets and seals can be manufactured in a variety of custom and standard shapes from a selection of silicone materials.

Quality Controlled Silicone Production

Boss Polymer has developed a rigorous quality control system specifically for silicone production. This allows for precise control over the manufacturing process to ensure only the highest quality silicone products are delivered to the marketplace.

Discuss Your Silicone Façade Needs

Contact the Boss team to discuss your Silicone Façade Gaskets and Seals requirements.