Home » Rubber Extrusions & Profiles » Noise Reduction Gaskets

Specialising in Rubber Noise Reduction

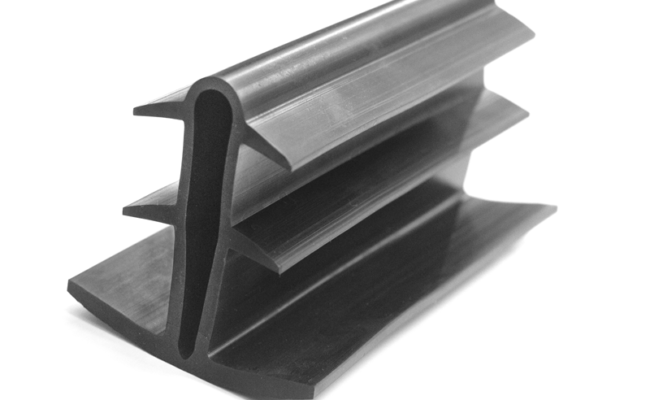

Boss Polymer specialises in the design and manufacture of rubber noise barrier gaskets, which are essential for reducing noise and vibration.

An Innovative Alternative to Traditional Methods

Traditional methods for filling wide and uneven gaps in vertical areas, often requiring skilled personnel to wait for suitable weather conditions to build up layers of caulking compound, generate significant on-site waste.

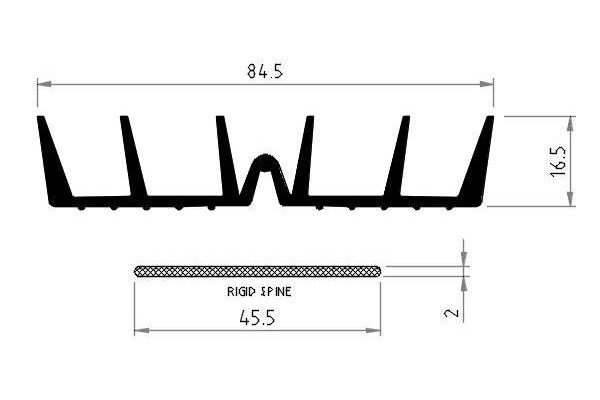

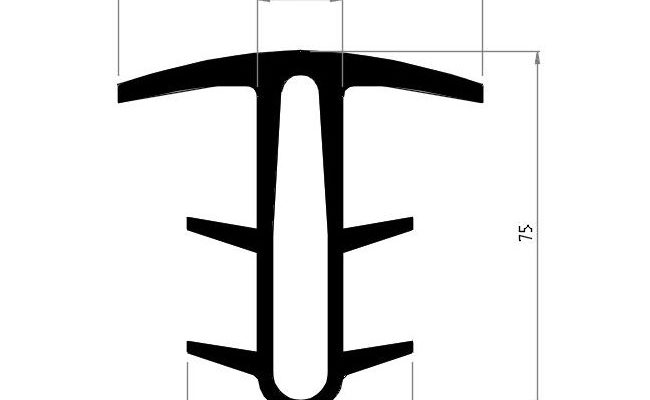

The Boss Polymer engineers designed the SpineSeal® as a weather-resistant rubber seal that can be installed efficiently and effectively in any weather condition. While the original SpineSeal® was developed in silicone, Boss Polymer offers expertise in creating custom rubber noise barrier gaskets that overcome the limitations of traditional methods, minimising on-site waste.

How Rubber Noise Barrier Gaskets Work

Rubber noise barrier gaskets function by blocking and diffusing sounds from sources such as traffic, industry, and domestic noise. Boss Polymer ensures that all related rubber components are designed to adhere to standard statutory regulations and design constraints for effective noise reduction.

Applications for Boss Polymer Rubber Gaskets

Boss Polymer’s rubber noise barrier gaskets have been utilised in various applications, including freeway and highway construction, main roads with high traffic efficiency, power enclosures, and commercial properties adjacent to residential areas. Boss Polymer also provides rubber noise barriers for new housing estates, developer-funded projects, and railway sites to help reduce potential noise pollution.

Discuss Your Rubber Noise Reduction Needs

Contact the Boss team to discuss your unique Rubber Noise Reduction Gasket requirements.