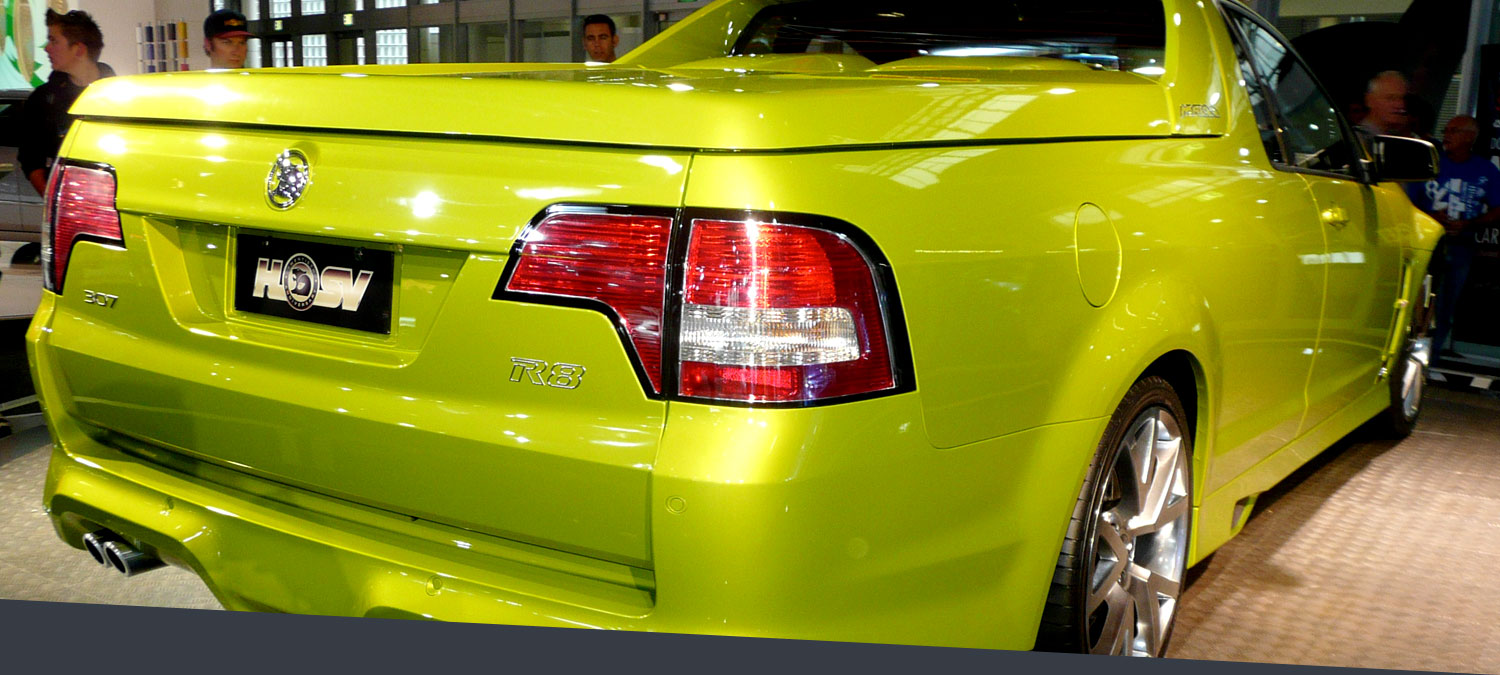

Boss Polymer Technologies was approached by GM Holden’s glass supplier, Saint-Gobain Sekurit. Saint-Gobain commissioned Boss to produce a high performance, life of vehicle weather seal with no separate fixing components. This seal was installed between the door and quarter window on the new Holden HSV GTS Maloo Ute. The solution used was the BossWeld system, a patented co-extruded system that allows Boss to weld tape directly onto the thermoplastic extrusion. This creates a bond strength that is far superior to any other adhesive backed extrusion in the market place. Saint-Gobain’s product development program manager, Mr. Sak Suwannasri said that “Boss product development was fast,” he went on to state that Boss “did a good job of quickly getting the right polymer mix. There was no other easy solution and we are happy with the quality aesthetic finish achieved.”

Make an EnquiryHolden® Maloo Ute and the BossWeld®

Key Facts

1st

Winner

BossWeld® was an Automotive Engineering Excellence Award winner from SAE Australasia for this technology.

80

Years

Saint-Gobain are recognised as one of the top 100 industrial groups in the world with over 80 years of experience.

5

Months

Developing the correct elastomer compounds and identifying self-adhesive tape that met GM Holden standards took over 5 months.

Recommended By GM Holden

Saint-Gobain Sekurit is a leading manufacturer of car glazing with over 80 years of experience. Saint-Gobain are recognised as one of the top 100 industrial groups in the world, with headquarters in Paris. The organisation employs around 193,000 people across 64 countries. Saint-Gobain Sekurit is the glass supplier for GM Holden and was commissioned to source and supply an external weather seal for the Holden HSV GTS Maloo (Gen-F VE Ute).

Having worked closely with GM Holden engineers in the past, Boss Polymer Technologies was recommended to Saint-Gobain. Saint-Gobain approached Boss Polymer to produce a high performance, life of vehicle weather seal to be installed between the door and quarter window no separate fixing components. The solution was the BossWeld® system, a patented co-extruded system that allows Boss to weld tape directly onto the thermoplastic extrusion. This creates a bond strength that is far superior to any other adhesive backed extrusion in the market place.

BossWeld® System

The BossWeld® system is a winner of a SAE-A Automotive Engineering Excellence Award. This single extrusion process reduces material, labour and production costs and enables the customer to select the type of pressure sensitive self-adhesive tape best suited to the task.

The Holden VE Ute seal is highly visible on the vehicle and must function to meet strict weather, noise and vibration seal standards. Mr Norman Mills (managing director of Boss Polymer Technologies) stated that this seal “is in the cabin side air flow and must be flexible to conform to shape when the door is closed, yet firm to hold out passing air and prevent noise. The surface must also hold a very thin layer of low friction coating. To achieve a tight seal at high speed, we co-extruded two different grades of Santoprene® elastomer onto the pressure sensitive self-adhesive tape. For this component, GM Holden specified a life of vehicle strength bond and this required a high quality self-adhesive tape,” he said.

The VE quarter window is manufactured using the Saint-Gobain Sekurit “encapsulation” process in which the glass and the components used to fix it to the vehicle are placed in a mould. To hold the components together and provide the required sealing edges, a reaction injection moulding polyurethane compound is injected into the mould.

Streamlined Production Line Process

Saint-Gobain Sekurit product development program manager, Mr. Sak Suwannasri said that this system is designed to streamline the OEM’s production line process “Boss was our polymer engineering partner on the project, which took over five months to develop the correct elastomer compounds and identify the best self-adhesive tape to meet the GM Holden standards,” said Sak Suwannasri. “Boss product development was fast – they did a good job of quickly getting the right polymer mix. There was no other easy solution and we are happy with the quality aesthetic finish achieved.”

Boss supplies custom engineered BossWeld® seals to specialist automotive manufacturers such as EGR and ARB, which supply international aftermarket and OEM customers.