Home » Plastic Extrusions & Profiles » U-Channel

High-Performance Plastic U-Channels for Diverse Industrial Applications

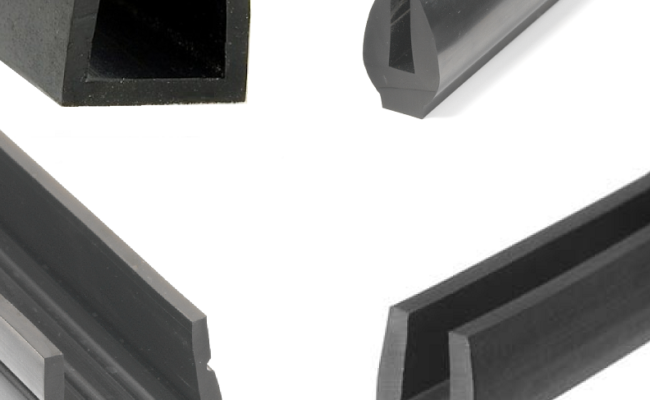

Boss Polymer is a leading supplier of sealing, edge protection, and trimming solutions, offering a comprehensive range of U-channels tailored to meet the diverse needs of various industries. Our commitment to innovation and quality has led to the development of advanced plastic U-channels, engineered for optimal performance in light to medium-duty applications.

Key Advantages of Boss Polymer Plastic U-Channels

- Lightweight Construction: Our plastic U-channels offer a significant weight advantage over traditional rubber channels, reducing overall load and simplifying handling and installation.

- Corrosion Resistance: Manufactured from high-grade polymers, our plastic U-channels are inherently resistant to corrosion from chemicals and UV exposure, ensuring long-term durability in harsh environments.

- Cost-Effectiveness: Plastic U-channels provide a cost-effective alternative to rubber channels, offering a balance of performance, longevity, and value.

- Ease of Installation & Low Maintenance: Designed for simple installation, our channels can be easily fitted to various edges and surfaces. Their corrosion-resistant properties also minimise maintenance requirements.

Applications

Boss Polymer plastic U-channels are ideally suited for a wide range of applications, including:

- Sealing and Edge Protection

- Trimming

- Furniture Finishing

- Various industrial applications

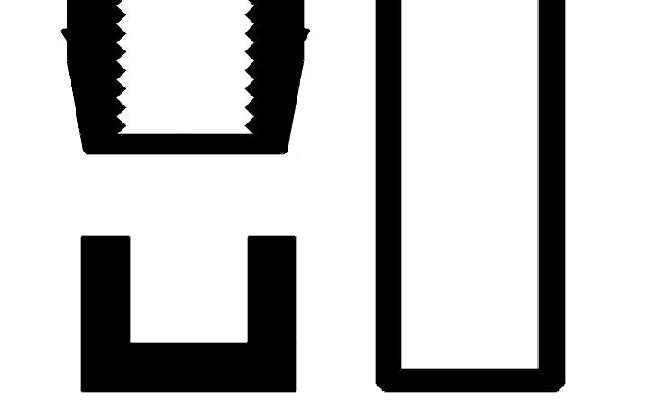

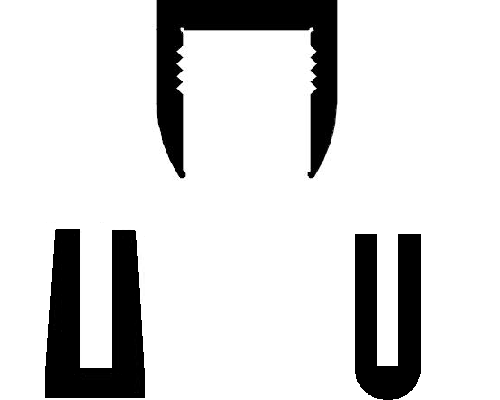

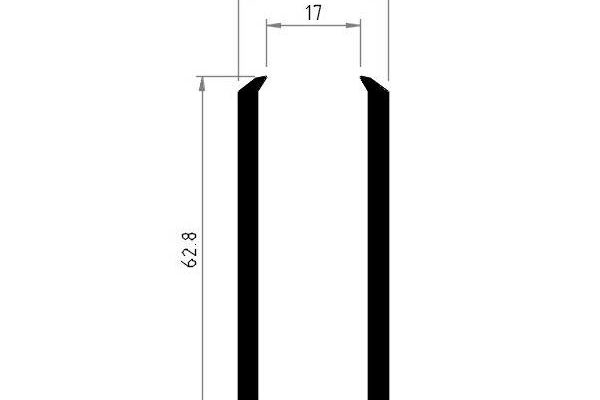

Custom U-Channel Solutions

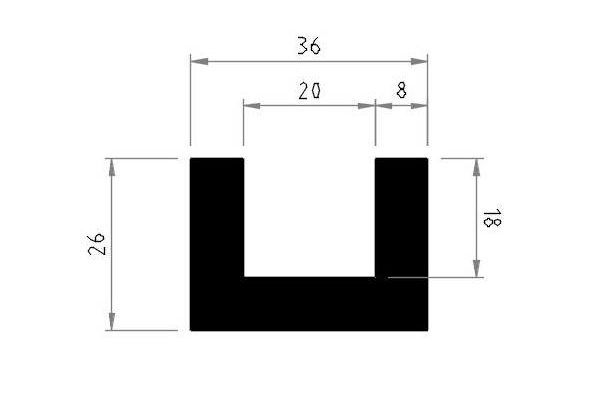

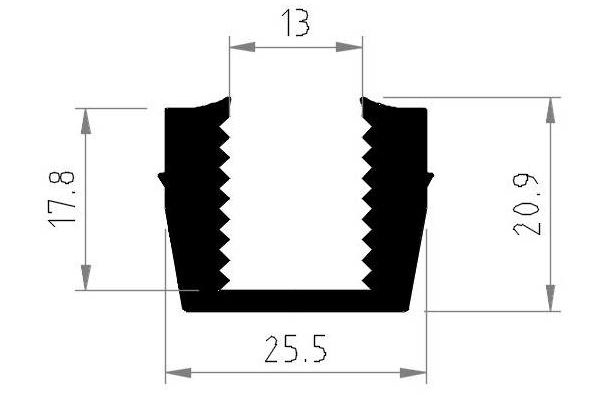

Understanding that every application is unique, Boss Polymer specialises in custom U-channels. Our engineering expertise and advanced manufacturing capabilities allow us to create bespoke solutions tailored to specific profiles, sizes, and performance requirements. Whether you need a specific colour, dimension, or material composition, our team can deliver a custom u-channel solution that precisely meets your needs.

Contact the Boss Polymer team today to discuss your U-channel requirements and discover how our innovative U-channel solutions can optimise your operations.