Home » Plastic Extrusions & Profiles » Mouldings

Plastic Moulding Capabilities

Boss Polymer offers custom plastic moulding facilities to manufacture plastic products precisely to your unique design and specification. Alternatively, we possess the expertise to provide advice on the optimal plastic design for your specific application.

Our in-house plastic capabilities include:

- Plastic product design and consultation service

- Plastic tool design

- Plastic research and development

- Plastic product development and testing

We offer a comprehensive range of thermoplastic polymers for moulded plastic products. Some of these standard plastic compounds meet regulatory specifications, including food grade plastic, fire retardant plastic, anti-static plastic, and potable water requirements. Should your plastic moulding have special requirements, Boss Polymer will collaborate with you to develop a custom plastic solution.

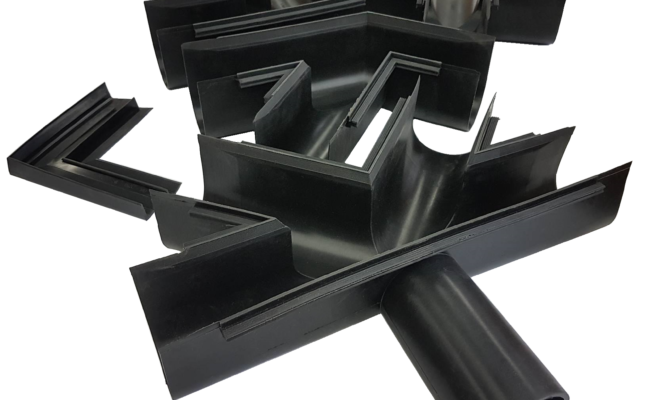

We are also capable of producing large and complex plastic mouldings, with applications in the civil, rail, construction, and mining industries. If re-engineering or re-design services are needed for your plastic moulding, Boss Polymer can work with you to help reduce costs or enhance the performance of the plastic moulding.

Lead times for new plastic products or the transfer of existing plastic parts are minimised. Post-moulding services for plastic products, such as packaging or assembly of multiple plastic parts, are available. Boss Polymer provides defect-free plastic products with on-time and complete delivery, contributing to cost reduction and efficiency improvement through optimal plastic design and manufacturing. Plastic products manufactured include:

- Moulded plastic end caps

- Plastic O-rings

- Plastic Washers

- Plastic Mouldings and Seals

- Plastic Sub-assemblies

- Plastic Pipe Gaskets

Contact the Boss Polymer sales team and let us develop a Plastic Moulding solution that best suits your application and needs.