Boss Polymer specialises in the design and manufacture of Marine and Industrial Fenders, and has recently worked with Aircraft Support Industries group (ASI), to design and manufacture a Co-extruded industrial fender. ASI is a world leader in the design and construction of Aircraft Maintenance Facilities, responsible for the design and construction of over 80 hangar facilities worldwide since its inception over 25 years ago.

ASI recently received a Letter of Award from SIA Engineering Company (SIAEC), leaders in Aircraft Maintenance, repair and overhaul services, to numerous International Airlines in the Asia Pacific . ASI has been contracted to design, build and install a new A380 dock in Changi Airport, Singapore. ASI approached Boss to design and manufacture a high grade industrial fender for the project.

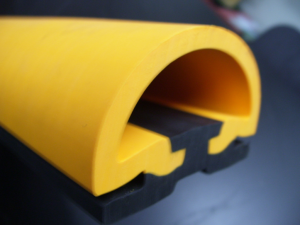

This Highly Specialised Thermoplastic Fender is designed to be installed in the Gantry of SIAECs New A380 Dock, to protect the Aircrafts Outer Surface from damage during maintenance. This Fender has been Co-Extruded, a process of Melding Multiple Compounds together, to gain their various benefits in a single extruded profile. The yellow visible section of the Fender uses a compound that is UV Resistant and Flexible, allowing it to compress and protect the Aircraft’s surface. The black section of the Fender uses a harder compound, allowing the profile to grip firmly onto the Gantry.

ASI states that they are looking forward to providing SIAEC with a Docking System, and Boss Designed Fender, that will further enhance the reputation of SIAEC as a leading facility and provider of maintenance to the Aircraft Industries.