It’s no secret that Boss is highly committed to investing in R&D and state-of-the-art equipment, materials and processes to better serve the needs of our valued customers. This year the Boss team has been working hard to develop new products, systems and procedures as well as purchasing new equipment and machinery. Amongst the many new initiatives is a new automated pallet wrapping machine and plastic inner cones.

It’s no secret that Boss is highly committed to investing in R&D and state-of-the-art equipment, materials and processes to better serve the needs of our valued customers. This year the Boss team has been working hard to develop new products, systems and procedures as well as purchasing new equipment and machinery. Amongst the many new initiatives is a new automated pallet wrapping machine and plastic inner cones.

Over the last few weeks, our customers may have noticed a change in the way their pallets have been supplied to them. The new state of the art stretch wrapper expertly wraps each individual pallet automatically to provide a consistent and repeatable high quality wrap and finish. This ensures that our products will get to our customers  securely and with minimal to no crushing of the product, hence minimising or eliminating product distortion and damage during transport.

securely and with minimal to no crushing of the product, hence minimising or eliminating product distortion and damage during transport.

This new equipment also allows Boss to gain an accurate gross weight of each pallet that will be written on the outside of each pallet. This allows our customers to safely store products, and improve their safe material handling processes.

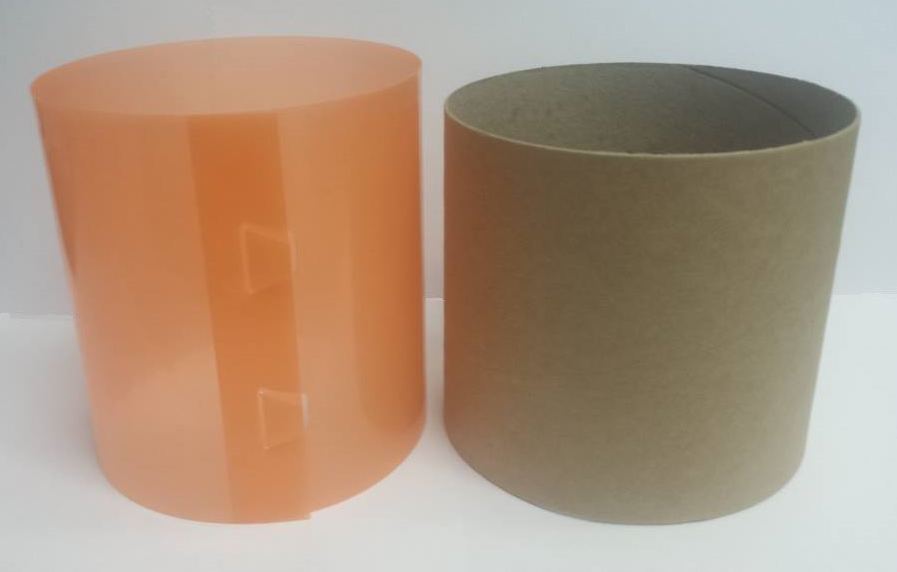

Additionally, in an effort to improve recycling at Boss Solar, the team are now using plastic cones made from recycled materials. These plastic cones replace the older styled cardboard cones previously used, which were generally discarded on site by the installer, creating waste. The advantage of the plastic cones is that they can be disassembled and stored flat, allowing our customers to easily return them to Boss to be reused.

These advances are set to improve our customers’ satisfaction and the environment. If you’re interested in finding out more send us an email at [email protected] or give us a call on (03) 9561 2777.